High Quality

Coupling

Specifications:

- Power transmission

- Shock absorption

- Flexibility

Industrial Couplings

Industrial couplings are mechanical devices that connect or couple two rotating shafts, allowing them to transmit power or motion. They are used in various industries and applications, such as power generation, oil and gas, metal, mining, marine, and railway. There are different types of industrial couplings, such as gear, diaphragm, disc, fluid, and universal couplings, each with their own advantages and disadvantages. Some of the factors that affect the selection of industrial couplings are torque, speed, misalignment, vibration, temperature, and maintenance.

Backlash Free Couplings

Our couplings serve as a modular interface between motor and work machine to ensure reliable and backlash-free power transmission in servo- and positioning drives.

Flexible Couplings

mateable and easy to assemble. The elastomer element compensates for shaft misalignment and absorbs impacts from the motor or work machines.

Highly Flexible Couplings

Well-suited to connect asymmetrically operating machines. They are used preferably in periodically stimulated systems.

TORSIONALLY RIGID COUPLINGS

Well-suited to connect asymmetrically operating machines. They are used preferably in periodically stimulated systems.

Railway Couplings

Whether between motor and gear unit or between gear unit and axle – rail couplings have proven themselves thousands of times in virtually every kind of rail vehicle worldwide.

Disc Couplings

Disc couplings offer precise positioning with zero backlash, even in rough or reversing applications. They can transmit high torque loads with power efficiencies of 99+ percent, long operating life (typically from 20 to 30 years), no maintenance, precision balance and in some units, the center spacer can cover long spans.

Grid Coupling

A multi-piece mechanical shaft coupling used to transmit torque and rotation between shafts in mechanical power transmission assemblies. Their design allows them to accommodate the slight variations in alignment that occur between connected shafts, while also absorbing shock loads.

Chain Couplings

Chain couplings transmit high torque loads in compact spaces. Consisting of two sprockets, a double-strand roller chain, and a coupling cover, chain couplings connect two shafts to deliver efficient power transmission in applications exposed to vibration and misalignment.

Disc Pack Couplings

Whether between motor and gear unit or between gear unit and axle – rail couplings have proven themselves thousands of times in virtually every kind of rail vehicle worldwide.

Elastomer couplings

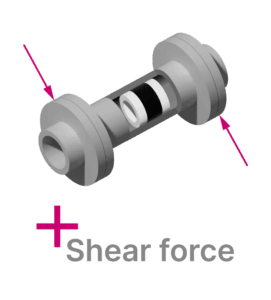

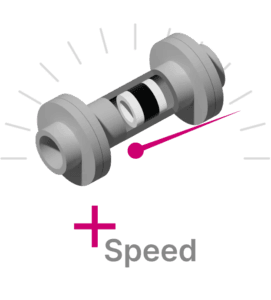

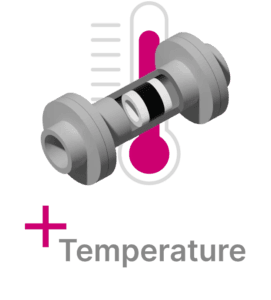

Elastomer couplings are characterized by a completely backlash free design, which is achieved by a special jaw geometry and preloaded elastomer insert.

The elastomer inserts are available in various Shore hardness values which enable the coupling to be adapted precisely to the damping, torsional stiffness, and misalignment compensation requirements of the application.

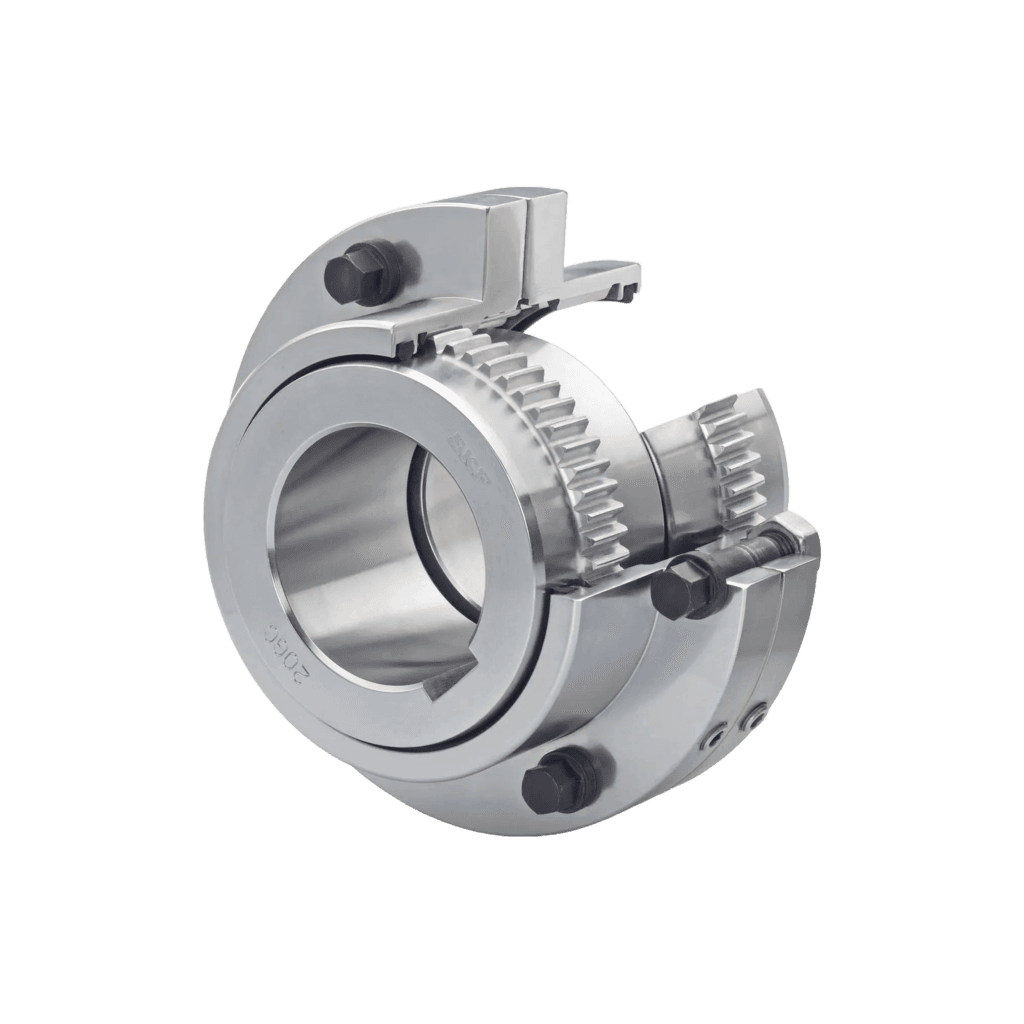

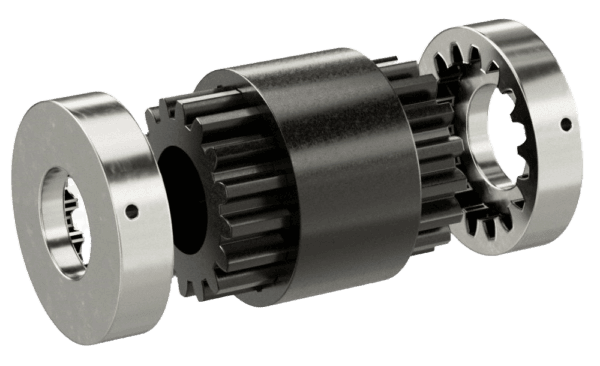

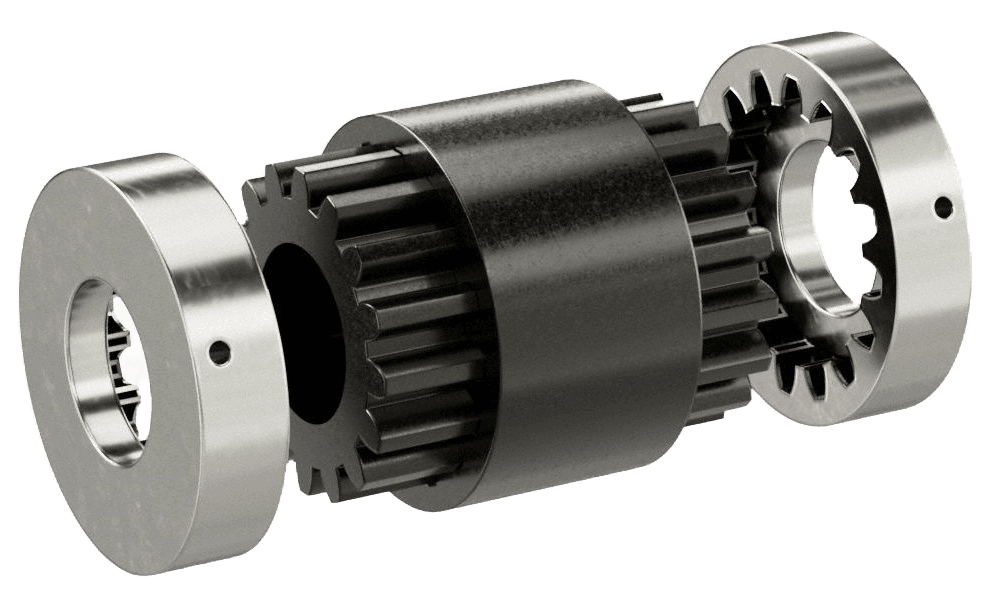

Gear Coupling

Chain couplings transmit high torque loads in compact spaces. Consisting of two sprockets, a double-strand roller chain, and a coupling cover, chain couplings connect two shafts to deliver efficient power transmission in applications exposed to vibration and misalignment.

Line shaft couplings

Line shaft couplings are used to span large distances between drive components. High precision intermediate tubing is combined with end hubs and flexible elements suitable for the application. In addition to metal bellows, elastomer inserts, and rigid hubs, special designs with flexible disc couplings are also available for this product.

For extremely long distances, intermediate supports or pillow block bearings can also be used between multiple line shaft couplings.

Oldham Couplings

Oldham couplings are 3-part couplings consisting of 2 hubs + 1 torque disc. The hubs determine the method of installation and shaft attachment, the discs determine the quality of motion.

Tire Coupling

a highly flexible rubber fabric coupling appropriated for compensation of big shifting and shock energies. Its remarkable high elasticity makes it possible to compensate extremely large offsets in all directions without generating wear. Free from backlash, it is the appropriated coupling to absorb torque peaks and dampen vibrations, due to its quick smoothing qualities.

Sleeve Couplings

Sleeve couplings join drive motors and equipment efficiently, while protecting against misalignment, vibration and shock loads. Each unit consists of two hubs or flanges and one insert. The flanges can be bushed bore or plain bore for direct shaft mounting, or they can be paired with compatible shaft-mounted spacers.

Other Types

Manufactures

Request

Get Your Free Quote right now!

High-quality products, reasonable prices

The All Known

Al-Hulul Al-Mustaqbilah Company.

comprehensive services and retail sales for both large and small industrial spare parts, as well as industrial tools and their accessories.